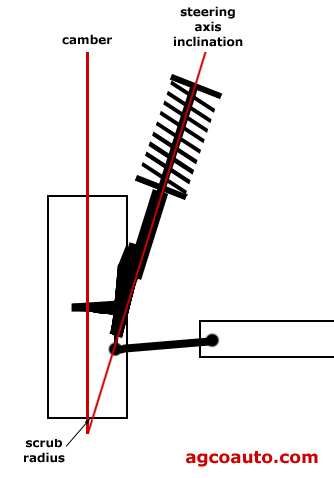

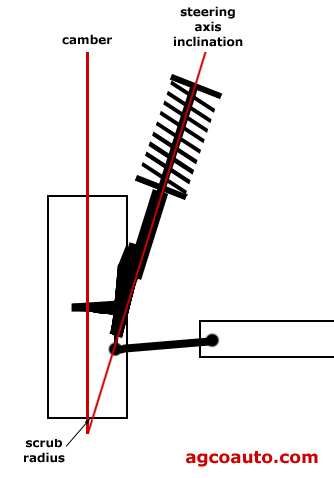

When a suspension is designed, it is from a specific ride height. This height is one important factor in the geometry of the suspension. Very basically, there are three major angles, camber, steering axis inclination (SAI) and included angle.

Camber = Included Angle - SAI

Included Angle = Camber + SAI

SAI = Included Angle - Camber

Camber is the angle a wheel varies from the true vertical. A wheel with zero camber is equal to true vertical and stands straight up and down. Improper camber results in tire wear so it is very important to the driver. Too much positive camber wears the outside of the tire. Too much negative camber wears the inside of the tire.

Steering axis inclination (SAI) is the angle between a line through the suspension pivot points and the true vertical of the wheel. SAI is important because it controls camber and scrub radius. Scrub radius is the difference between the line of camber and the line of SAI, at the surface of the road.

Scrub radius controls tire wear and handling. It also determines where the alignment must be set to prevent tire wear. Factory specifications take this into account. Change scrub radius and the alignment requirements change, to an unknown value. Setting the alignment to factory specifications may no longer stop tire wear. The actual specifications needed can be almost impossible to determine.

When a vehicle’s height is changed, the SAI and camber will also change. This is because the linkage that connects the wheel to the chassis travels through an arc. Change the position in the arc and the effective distance between the mount points changes.

Lowering the vehicle, as in the picture, causes the bottom of the wheel to move out, resulting in negative camber.

Since negative camber wears the inside of the tire, efforts might be made to correct it. In a suspension, SAI plus camber equals included angle. If any of the three angles change, another angle must also change. Changing SAI also changed camber.

On a vehicle without adjustments this cannot be corrected without modifications. There are aftermarket kits that replace the bolts that hold the strut to the knuckle. Because these bolts are smaller than the originals they allow slack in the mounting.

On a vehicle without adjustments this cannot be corrected without modifications. There are aftermarket kits that replace the bolts that hold the strut to the knuckle. Because these bolts are smaller than the originals they allow slack in the mounting.

Moving the strut to knuckle mounts provides a means to restore camber. Unfortunately it does so by changing included angle. This changes the scrub radius and the alignment requirements. Even though camber has been restored, tire wear and poor handling may well continue.

Once the suspension is modified:

Original specification no longer apply

Original specification no longer apply

The dynamic alignment can be altered

The dynamic alignment can be altered

Handling will be affected

Handling will be affected

It is not possible to determine proper alignment settings without a good deal of trial and error

It is not possible to determine proper alignment settings without a good deal of trial and error

The pivot points, such as ball joints and tie rods will also be affected. These components are designed to operate within a narrow range. With the vehicle at normal height, the stud in the joint is centered. From this position, it can move adequately to accommodate jounce and rebound of the suspension.

The pivot points, such as ball joints and tie rods will also be affected. These components are designed to operate within a narrow range. With the vehicle at normal height, the stud in the joint is centered. From this position, it can move adequately to accommodate jounce and rebound of the suspension.

When the vehicle suspension is raised or lowered the stud is no longer in the center of its travel. Because the position of the component has changed the stud is positioned to one side or the other. Now when the suspension moves up or down during jounce or rebound, the joint will over-travel. This quickly wears the parts and can cause breakage.

When the vehicle suspension is raised or lowered the stud is no longer in the center of its travel. Because the position of the component has changed the stud is positioned to one side or the other. Now when the suspension moves up or down during jounce or rebound, the joint will over-travel. This quickly wears the parts and can cause breakage.

Bushings are designed much the same way, with a range of travel. A great deal of engineering goes into the modern vehicle suspension and it is largely based on the specified ride height. On an alignment machine this can easily be seen. Push a perfectly aligned vehicle up or down about an inch and the alignment readings go out of range.

Only by returning the vehicle to original height or completely re-engineering the suspension can wheel alignment be achieved. Changes to vehicle height should not be taken lightly. When changes are made, repercussions will result. Correction can be very expensive and time consuming. This may be worth considering before modifying the vehicle ride height.

Original specification no longer apply

Original specification no longer apply